Recollect when the sewing machine was the most recent mechanical development in clothing creation, a period where proficiency immediately turned into the cutting edge worry of each design brand. Today, we face a daily reality such that design and innovation are coordinated as one. Presently, we see the development of advanced mechanics in the design business rather than the cliché Hollywood film robots that assume control over the world. From artificial reasoning to brilliant machines, robots have changed the game for style, yet in what ways? Differences in machine size, capacity, and cost have required attire organizations to reconsider putting resources into incorporating this new influx of innovation into their tasks. Here is the why and how of it.

The Breakdown on Purchasing and Implementing Fashion Robots

As per the International Federation of Robotics (IFR), the modern advanced mechanics market is set to see an average development pace of 14%, somewhere in the range of 2018 and 2020. Style producing has become progressively complicated because of an expansion sought after alongside a shortage of talented laborers. Robotic technology has and will keep on working on the creation cycle in manners we’d never anticipate. We should investigate potential advanced mechanics that can coordinate into the creation cycle without much of a stretch.

- Enunciated Robot

- Cartesian Robot

- Scara Robot

- Equal Robot

The most well-known robot is the Articulated robot. This machine utilizes a rotating joint framework to get done with jobs like gathering, pick and spot, material evacuation, investigation, bundling, and administering. The Cartesian robots move in long straight tomahawks anyway. They’re not difficult to program and genuinely productive. The Scara robot chips away at the upward plane just as the direct, making them quicker and more adaptable than the Cartesian framework.

In conclusion, the Parallel robot can perform sensitive and exact developments because of its verbalized parallelogram base. These robots are consequently constrained by programming, can be reconstructed, and can convey our different capacities. From a reprogrammable cerebrum, explicit programming guides the mechanical framework to develop the suitable capacity expected to wrap up a given job.

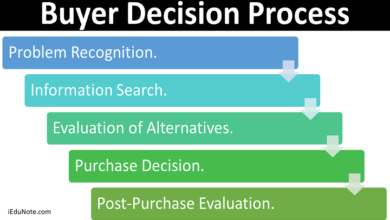

Sliding into the universe of computerization is the ideal way of seeing how to apply it straightforwardly to your strategic approaches. It’s crucial to take a gander at your present assembling activities to conclude whether using robots best meets your requirements as a style brand, little organization, or not. With the rising interest in clothing, organizations face the test of time and create vital ways to beat this test. For a vast scope, programming controlled robots can regularly wrap up jobs all through warehousing habitats like moving materials and products, with superhuman speed and accuracy, making the conveyance cycle more effective. As additional time and cash is put into investigating innovation, advanced mechanics in style creation will keep on expanding immensely.

According to the maker viewpoint, the central inquiry on fusing automated frameworks transfers back to speculation cost. Modern robots can run altogether from $50,000 – USD 150,000, relying upon the difference in applications and the establishment cost. Nonetheless, reconditioned robots are more affordable and can cost as low as USD 25,000. On a more limited size, explained robots as the entire mechanical arm starts at $5,000. However long the automated frameworks have an appropriate work area and undertake explicit applications introduced, there will be a good expansion in proficiency in return for these speculations. Indeed, even with the more modest, single capacity robots, brands can task these instruments to finishing one excess responsibility rather than the whole interaction, actually bringing down their generally staffing needs on the production line floor just as normalizing specific floor errands.

One thing to consider is how amazingly troublesome it is for design brands to take on these practices and apply them to their everyday tasks. Specialized troubles and human work requirements stay the most significant worries that keep industry pioneers away from embracing the computerization cycle. With an end goal to forestall incidents, innovation organizations are searching for elective ways of bettering determination how to utilize mechanical technology to serve the style business.

Mechanical Solutions in Real World Fashion Production

Moving over to the natural formation of clothing, the careful assignment of working with delicate material and textures has relied upon multitudes of human workers (regularly came up short on). Or if nothing else, as of not long ago! Jonathan Zornow is the maker of Sewbo, a sewing machine robot that artificially solidifies the texture to create a completed piece of clothing. Like this, he improved on the troublesome interaction working with fragile material by making it viable with the robot. This completely computerized process is still exceptionally new, and bars textures like fleece and calfskin yet have gained enormous headway pushing the universe of style mechanization ahead.

Another game-changing mechanical advancement is the Sewbot known as LOWRY, made by Software Automation. Adopting an alternate strategy, this Sewbot utilizes an aligned machine with cameras to break down suitable contortions in the texture. It can cut, sew, add texture, assess for quality, and adjust to one-of-a-kind item determinations with the press of a button. The machine vision framework has higher precision than the natural eye while investigating materials, making a better final result. These robots start at $5,000 each month with a noteworthy item limit of up to 1 million.

The more organizations settle existing issues that accompany design fabricating, the more they’re leaned to coordinate profoundly mechanical devices into creation. Mechanical frameworks are a simple way of computerizing errands while decreasing creation and work costs related to dreary cycles.

With the considerable scope of automated frameworks, improving the assembling system has never been so natural. Indeed, cost plays a significant component in the choice dependent on organization assets, but as innovation progresses, these instruments will become more affordable and more available.

Rather than exclusively assessing enormous, costly robots housed in the super durable framework of your claimed maker offices, you can move your concentration to tiny independent, impromptu robots that take care of business. Doing this dispenses with the utilization of modest work in return for exceptional items, at unequaled low expenses, to all the more likely enable your makers to convey quality items quicker.